Punching

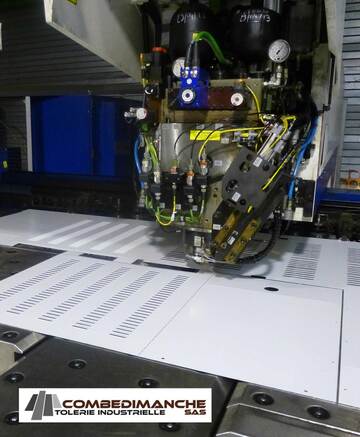

3 Industrial Punching Center :

Our Industrial Punching near from VALENCE (26000) is composed of three Automatic Punching Centers who allow us to answer quickly to all your needs.

On these Punching Machines with numerical control, we can produce until 4000 x 1500 mm maximal on Sheet Metal size with automatic system any Steel Metal pieces, Galvanized Sheet, Aluminium, Lacquered Sheet or Polypropylene into little, medium and big batch.

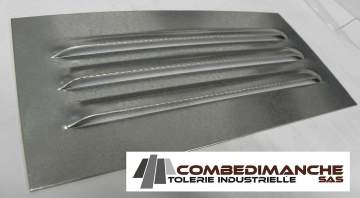

We advise you The Industrial Punching for pieces with maximal thickness 4 mm having an angular form with different punch, matrix, thread, knurling, ribbing tools and we could make many proceedings who will require us some recoveries on Laser Cutting.

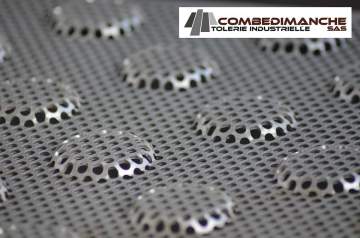

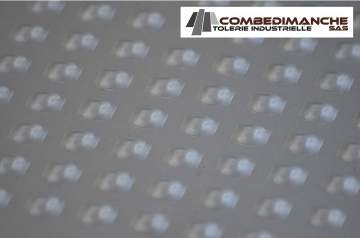

In Punching Centers, we'll be able to perform anti-slip floors with a wide choice of stampings, stairs steps, perforated decorative sheets, reinforced by stiffening with stampings or the ribbing of your metal panels.

Our longuest Punching experience will allow us to find the economical and industrial solution to all your requests and we'll be there to advise you.

The Industrial Punching remains to be an economical alternative for many thin sheet metal workshop pieces with a lot of means by keeping an excellent quality of pieces.

Remplace your gratings by perforated anti-slip floors with a different design and a suitable rigidity.

We are the first Company who bought a Puching Center with a large active matrix.

The Process

Punching is a kind of shearing operation carried out along a closed contour, done by applying a punch (male component) onto a die (female component). The same principle is used for shearing. A hole or opening is created by means of compressive stress.

This process is generally used in the sheet metal industry to make holes and to cut the flanks of complex shapes which are sometimes not rectangular in shape and therefore difficult if not impossible to produce using shearing.

Parts that require a lot of holes are generally manufactured using this technique, as it is less expensive than laser cutting and also due to the low deformation on the parts.

For surface finished steel sheets, the cutting zones are better protected using this procedure.

The Punching Specialist

With our two Automated Punching Workshops, COMBEDIMANCHE can offer you an interesting alternative to Laser Cutting.

We can handle metal sheet formats of up to 3010 x 1600 with a maximum thickness of 4 mm and automatic tapping, milling, Rolling rib and Rolling offset operations are possible with different metals such as Steel, Stainless Steel, Aluminium, pre-painted/coated sheets, copper, brass, plastic, Dibond plates and metal bond.

Why not come and see us and find out how can you reduce the thickness of your metal sheets while keeping the same durability thanks to Ribbing/Belchering?

ACURACY, FINISHING, LOW PRICE : TRY PUNCHING !

Our Punching Technical Specifications :

| Name | Metal Sheet Format | Thickness | Punching Power | Max Stroke Rate | Max Number of Tools | |

| TRU PUNCH 5000 | 3010 x 1600 |

Max : 4 mm |

220 KN | 1000 Per Minute | 21 Tools + 4 Clamps | Fully Automated |

| TRUMATIC 500 rotation | 2500 x 1250 (Option : 4000) | Max : 4 mm | 220 KN | 900 Per Minute | 17 Tools + 3 Clamps | Automated Loading / Unloading |