Bending

8 Bending Press

The Process

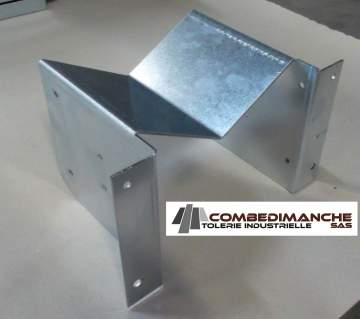

Bending is a manufacturing process that produces a V-shape, U-shape or channel shape along a straight axis in ductile materials, most commonly sheet metal.

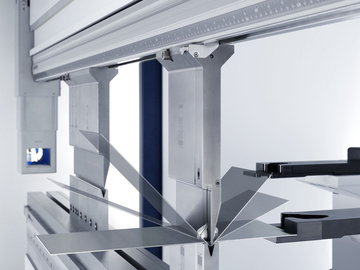

The machine used (Press Brake) is fitted with a V-die and a punch.

The metal sheet can be bent in two different ways:

- Air Bending: Where the punch does not fully reach the bottom of the V-die (varying press-stroke depth)

- Coining: where the top tool forces the material into the bottom die.

Using our Press Brakes, unitary parts or series of up to 5m in length can be bent (Steel, stainless steel and Aluminium) with a die-forging power of 20 to 500 tonnes – while always conserving a precise and consistent quality.

Bending Specialist

Our crew of Qualified Team offers you their sheet metal Bending expertise on our 7 state-of-the-art Press Brakes for parts of different sizes and thicknesses.

We know how to meet your individual expectations and needs: from single components to large runs ; from narrow parts to 5m ; from minimal thicknesses to 20mm ; working with Steel, Stainless Steel, Aluminium or Plastic

COMBEDIMANCHE Press Brakes are equipped with numerical control, large strokes (up to 420 mm), adjustable mechanical stops which adapt easily to complex parts, anti-twist correction, bending support for numerous V-dies and blades/punches.

With our Team of experienced Sheet Metal Bending Specialists and our wide range of Press Brakes we are ready to meet your prototyping and serial production needs promptly and efficiently, for flattened folds, pinching or traditional bending.

Press Brakes Specifications.

- With our TRUBEND 8400 Press Brake with a press force of 400 tonnes, we can handle bending lengths of 5000 mm maximum, with a thickness of 8 mm with laser controlled bending (LCB). For shorter bending lengths, we can bend parts up to a thickness of 20mm.

- With our 2 TRUMPF CN V230 Press Brakes (230 tonnes) and our EHT 110-30 Press Brake we can handle bending lengths of up to 3000 mm with angle sensors and 8-axis adjustable mechanical stops, bending support included.

- With our TRUMPF CV V50 (50 tonnes), we can handle bending lengths of up to 1250 mm with ACB and 4-axis adjustable mechanical stops.

Our CN COLLY Press Brake can handle specific bending operations.

What’s more, our TRUBEND 7036 Press Brake, with a press force of 36 tonnes can handle parts up to a thickness of 1020mm.